Dubo® toothed collar washers (steel and stainless steel)

Allow additional loading of the Dubo® retaining washer

The Dubo® toothed collar washers reinforces the properties of a Dubo® retaining washer. As a true Dubo® Original, it guarantees excellent quality. The toothed collar washer is made of steel or stainless steel and designed for use with high-quality 8.8 and 10.9 steel bolts. It keeps the retaining washer effective and intact, regardless of the force applied to it by the bolt.

Integrated retaining washer, toothed collar washer and nut

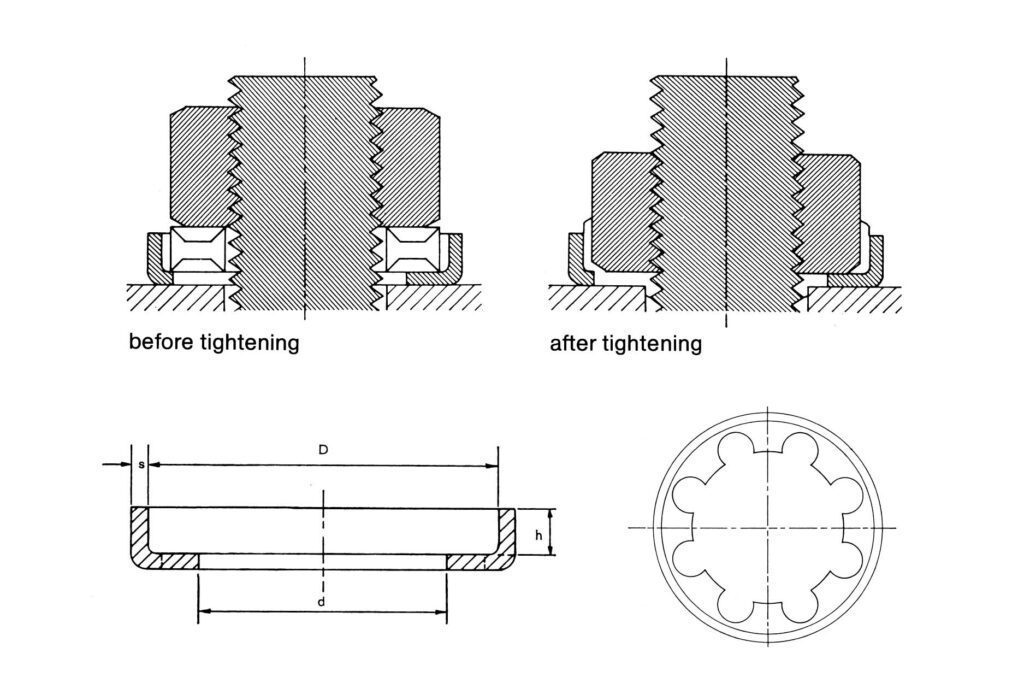

Dubo® toothed collar washers are designed so that the teeth perforate the retaining washer under high pressure. After the assembled pieces are deformed, the retaining washer forms a single whole with the toothed collar washer and the nut. This creates a partly rigid connection of steel/steel-nylon and constant elasticity of the retaining washer.

Maximum load capacity

If a Dubo® toothed collar washer is applied, any nut can be used and reused as a lock nut. If used in combination with a toothed collar washer, the Dubo® retaining washer can be loaded for any desired bolt force without the high load damaging the nut or bolt. Dubo® toothed collar washers are available in steel and stainless steel.

Advantages of Dubo® toothed collar washers

These toothed collar washers are Dubo® Originals; designed and produced by us since 1951. That means absolute quality and convincing advantages are guaranteed:

- Allow any bolt force to be applied to the Dubo® retaining washer

- Secure bolts against vibrating loosening due to excessive load

- Turn any nut into a locknut

- Reusable

- The locking material under the nut has sound-damping, sealing, and locking properties at a constant bolt force

- High coefficients of friction achieved by using Dubo® toothed collar washers in conjunction with retaining washers

- Dubo® retaining washers can be used at high temperatures (± 180 °C)

- Metallic contact (mass) is obtained where desired

- Good locking properties for stud bolts

| Part.No. | Material | Ref No. | Metric threads (Hexagon head screws) | Inch threads (Hexagon head screws) | Metric threads (Socket head screws) | Inch threads (Socket head screws) | D | d | H | s | packing unit/pcs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1504000000000 | steel | 404 | M 4/5 | 3/16" | M6 | 1/4" | 11,20 | 6,80 | 2,50 | 0,50 | 500 |

| 1604000000000 | stainless | 404 | M 4/5 | 3/16" | M6 | 1/4" | 11,20 | 6,80 | 2,50 | 0,50 | 500 |

| 1506000000000 | steel | 406 | M6 | 1/4" | 13,20 | 9,20 | 3,70 | 0,70 | 500 | ||

| 1606000000000 | stainless | 406 | M6 | 1/4" | 13,20 | 9,20 | 3,70 | 0,70 | 500 | ||

| 1508000000000 | steel | 408 | M8 | 3/8" | M10 | 3/8" | 17,00 | 12,00 | 3,90 | 0,90 | 500 |

| 1608000000000 | stainless | 408 | M8 | 3/8" | M10 | 3/8" | 17,00 | 12,00 | 3,90 | 0,90 | 500 |

| 1510000000000 | steel | 410 | M10 | 1/2" | M12 | 1/2" | 21,20 | 13,40 | 4,40 | 1,50 | 500 |

| 1610000000000 | stainless | 410 | M10 | 1/2" | M12 | 1/2" | 21,20 | 13,40 | 4,40 | 1,50 | 500 |

| 1512000000000 | steel | 412 | M12 | M14 | 24,30 | 15,40 | 4,70 | 1,50 | 100 | ||

| 1612000000000 | stainless | 412 | M12 | M14 | 24,30 | 15,40 | 4,70 | 1,50 | 100 | ||

| 1514000000000 | steel | 414 | M14 | 5/8" | M16 | 5/8" | 27,00 | 17,50 | 5,00 | 1,50 | 100 |

| 1614000000000 | stainless | 414 | M14 | 5/8" | M16 | 5/8" | 27,00 | 17,50 | 5,00 | 1,50 | 100 |

| 1516000000000 | steel | 416 | M16 | M18 | 31,30 | 21,40 | 6,00 | 1,60 | 100 | ||

| 1616000000000 | stainless | 416 | M16 | M18 | 31,30 | 21,40 | 6,00 | 1,60 | 100 | ||

| 1517000000000 | steel | 417 | 5/8" | M20 | 33,00 | 23,00 | 5,00 | 1,80 | 100 | ||

| 1518000000000 | steel | 418 | M 18/20 | 7/8" | M22 | 7/8" | 37,50 | 26,00 | 5,65 | 1,80 | 100 |

| 1618000000000 | stainless | 418 | M 18/20 | 7/8" | M22 | 7/8" | 37,50 | 26,00 | 5,65 | 1,80 | 100 |

| 1519000000000 | steel | 419 | 3/4" | M24 | 39,50 | 27,00 | 5,50 | 1,75 | 100 | ||

| 1522000000000 | steel | 422 | M 22/24 | 44,00 | 30,40 | 6,00 | 2,00 | 100 | |||

| 1622000000000 | stainless | 422 | M 22/24 | 44,00 | 30,40 | 6,00 | 2,00 | 100 | |||

| 1527000000000 | steel | 427 | M27 | 51,00 | 35,00 | 6,40 | 2,00 | 100 | |||

| 1627000000000 | stainless | 427 | M27 | M24 | 51,00 | 35,00 | 6,40 | 2,00 | 100 | ||

| 1530000000000 | steel | 430 | M30 | 56,00 | 40,00 | 7,30 | 2,60 | 100 | |||

| 1630000000000 | stainless | 430 | M30 | 56,00 | 40,00 | 7,30 | 2,60 | 100 | |||

| 1533000000000 | steel | 433 | M33 | 61,00 | 45,00 | 8,00 | 2,60 | 100 | |||

| 1633000000000 | stainless | 433 | M33 | 61,00 | 45,00 | 8,00 | 2,60 | 100 | |||

| 1536000000000 | steel | 436 | M36 | 67,00 | 50,00 | 8,60 | 2,65 | 100 | |||

| 1636000000000 | stainless | 436 | M36 | 67,00 | 50,00 | 8,60 | 2,65 | 100 |

- Dimensions in MM

Characteristics

Increase load capacity of Dubo® retaining washers

When combined with a toothed collar washer, a Dubo® retaining washer can withstand any load, even when using 8.8 and 10.9 bolts.

Excellent locking

- Regardless of the load on the retaining washer

- Bolts cannot vibrate loose

- Also good locking properties for tap bolts

Durable and usable in a wide range of applications

- Toothed collar washers can be reused multiple times

- Suitable for use at high temperatures (± 180 °C)

- A toothed collar washer allows any nut to be used as a lock nut

Uses of the Dubo® toothed collar washers

Can be used in combination with:

Dubo® retaining washers

Dubo® retaining washers are effective and easy to use. Dubo® retaining washers have a unique design which forces the nylon to encase the screw thread and the bolt hole when the connection is tightened. It offers an effective and cost-effective solution for manufacturers and installers who need permanent, durable locking.

Dubo® retaining washers for socket screws

Just like standard Dubo® retaining washers, these washers for socket screws are also very effective and easy to use. The nylon material forces itself around the thread and into the hexagonal bolt hole when the screw connection is tightened.

More info?

Disclaimer: All descriptions, technical information, drawings and dimensions on this website have been compiled by Dubo Dorned B.V. with the greatest care. Nevertheless, Dubo Dorned B.V. cannot accept any liability for type-setting and typographical errors, technical changes to the products or for any incidental or consequential damage in connection with our technical statements or our ability to deliver. All drawings and descriptions on this website are in no way of an agreed quality. The information herein concerns typical values intended for reference and comparison purposes only. It should NOT be used as a basis for design specifications or quality control. Contact us for full material property datasheets from manufacturers. Understandably, the application of the products listed assumes expertise on their use and assembly as well as standards. All our offers and any subsequent orders and agreements resulting thereof are exclusively subject to the General Terms and Conditions of Dubo Dorned BV.